|

|

|

Thermal Ink Jet (HP) printers are an ideal solution for

fast format change with very low cost per package print for small batch volumes. |

| THERMAL INK JET (HP) PRINTERS | |||||||||||

|

CU BAR CODE PRINTER The CU uses a keypad and flash card. Capable of printing 2-D bar codes. • Unlimited number of messages

|

||||||||||

| Click to download a printable information sheet in PDF format. You will need the latest version of Adobe Acrobat Reader to view and print these files. | |||||||||||

|

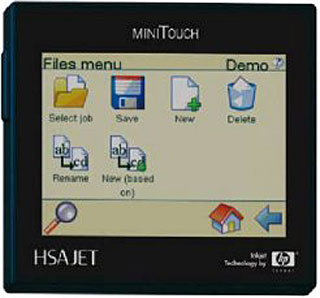

Mini-Touch USB INTERFACE The Mini-Touch has a user-friendly touch screen and interfaces through USB. • Unlimited number of messages • Connect via RS232 or EtherNet • Control the printer from anywhere in the production area • Print speeds up to 1600 mm/sec • Retrofits to all horizontal form, fill and seal packaging machines • Print resolution from 150 to 600 dpi • Fully programmable for fixed text, logos and graphics • Continuous or intermittent motion • Prints Linear and 2D scannable bar codes Packaging samples - Click to enlarge

|

||||||||||

| Click to download a printable information sheet in PDF format. You will need the latest version of Adobe Acrobat Reader to view and print these files. | |||||||||||

|

TIPC USER-FRIENDLY The TIPC has a user-friendly touch screen and is capabale of printing 2-D bar codes. • Unlimited number of messages • Connect via RS232 or EtherNet • Control the printer from anywhere in the production area • Print speeds up to 1600 mm/sec • Retrofits to all horizontal form, fill and seal packaging machines • Print resolution from 150 to 600 dpi • Fully programmable for fixed text, logos and graphics • Continuous or intermittent motion • Prints Linear and 2D scannable bar codes |

||||||||||

| Click to download a printable information sheet in PDF format. You will need the latest version of Adobe Acrobat Reader to view and print these files. | |||||||||||

|

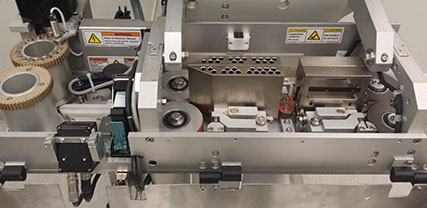

Specility Printer In compliance with the new UDI mandate for medical devices, our Model 5000P Plus system introduces Greydon GS1 Datamatrix printing and a Keyence 2D Code Reader to our existing Allen Bradley controlled rotary band heat sealer. A large 12" full color touchscreen HMI monitors and informs the user of all phases of operation. As with previous versions, the Model 5000P Plus is fully validatable with respect to speed, temperature, and force. Urania utilizes a real-time monitoring system for all three of these crucial sealing parameters. The operator imports the current lot information and sealing parameters to the Model 5000P Plus using a simple scan. The UDI printing and verification system then prints the GS1 code on the pouch, and verifies the information ... as part of the sealing process! Any rejected pouches are automatically diverted after exiting the system, and all information is logged through the HMI and its accompanying PC. The Greydon print head uses a disposable HP style cartridge and the ink dries instantly to the touch, even on poly materials. An alarm and error history with time/date stamp is standard. The alarm/error information may be downloaded to a customer supplied printer, compact flash, or through an Ethernet connection. Alarms for belt speed errors, force limits, and temperature variations ensure proper operation and immediate notification in the event of a problem. Various options are available such as conveyors and infeed devices, pouch trimming, and gas flush or nitrogen injection systems. The sealing head is mounted on our height adjustable, stainless steel stand with locking casters. |

||||||||||

| © 2014 Greydon, Inc. All Rights Reserved. |